Along with the advance of modern building technology, steel structure engineering because of its high strength, light weight, environmental protection and other advantages, more and more widely applied in the field of architecture.Steel structure project construction process of concrete is as follows:

Preparation in advance

The preliminary preparation includes the exploration of the construction site to understand the geological environment, traffic conditions, etc., in order to develop the appropriate construction plan.At the same time, it is also necessary to determine the walking route of the crane to ensure the safety and smooth progress of the lifting operation.

Material procurement and inspection

Steel is the core material of steel structure engineering.Before construction, it is necessary to purchase high-quality steel, welding materials, bolts and other raw materials according to the engineering needs, and carry out strict inspection.Ensure the quality of raw materials meet the national standards and design requirements, and provide a strong guarantee for subsequent processing and installation.

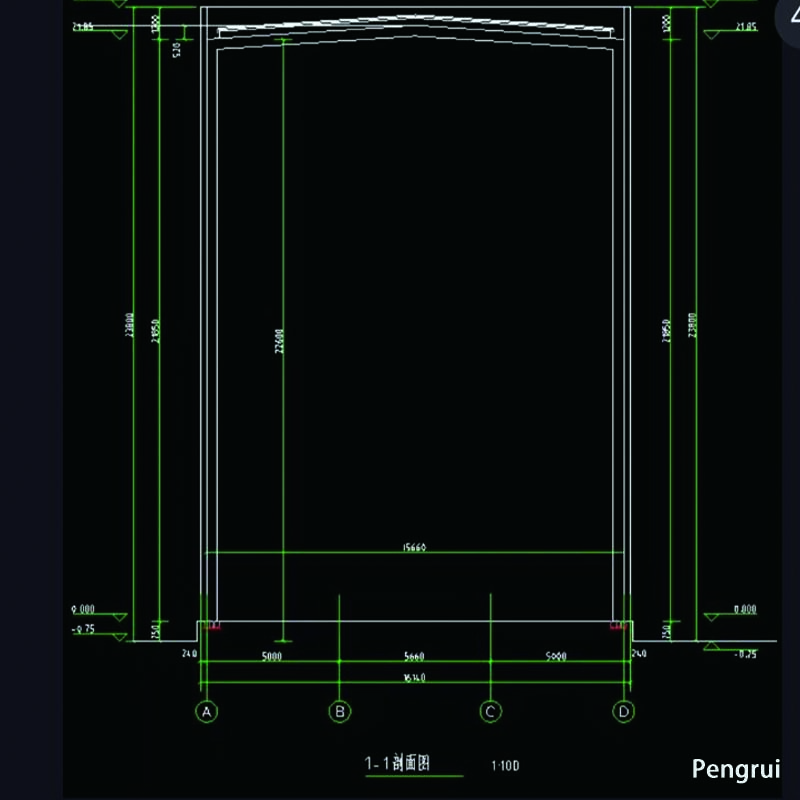

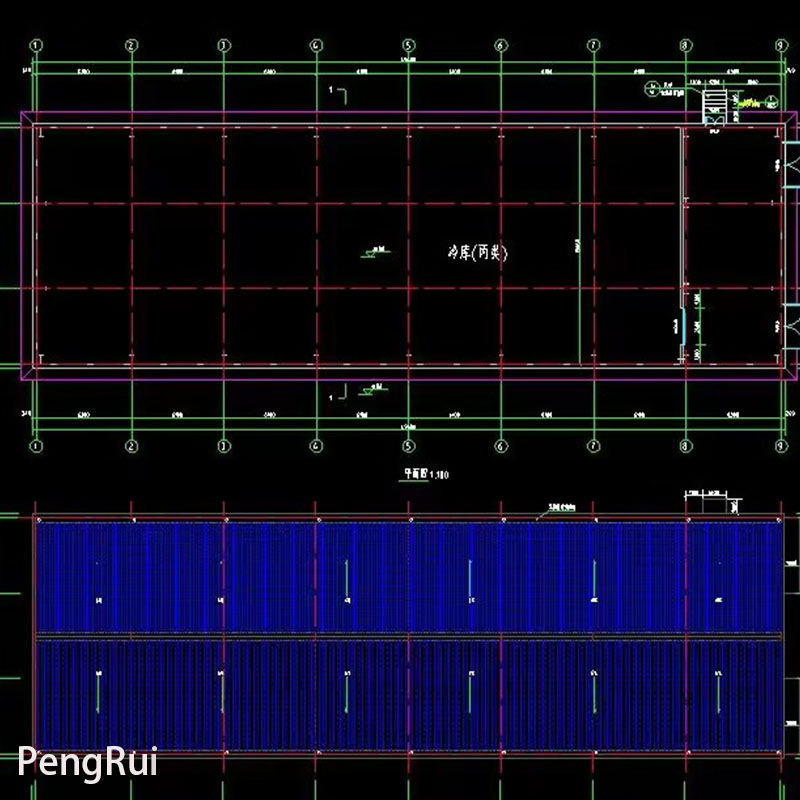

Cutting and production

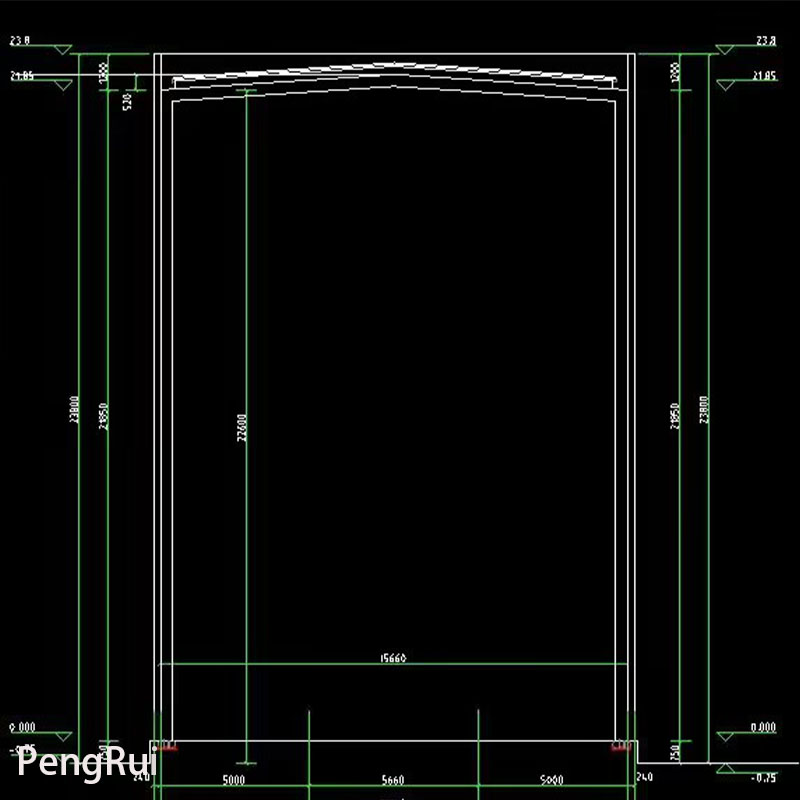

According to construction drawings and process requirements, raw materials are cut, welded and other processing and production to form various components and components.In the process, it is important to pay special attention to the components of precision and quality control, ensure that each component meet the design requirements.

Pre-assembly and rust removal skins

After the component is made, it needs to be pre-assembled.Through checking the prestressing assembled components, such as size, shape, Angle meets the design requirements, and make the necessary adjustment and correction. At the same time, the components are treated to remove rust and oil on the surface, and then painted with anti-rust paint and topcoat to protect the components from corrosion and damage.

Transportation and stacking of components

The completed components are numbered and classified, and the appropriate means of transport are selected for transportation.When stacking, it is necessary to take into account the sequence of site installation and the deformation of components, and take corresponding measures to protect.

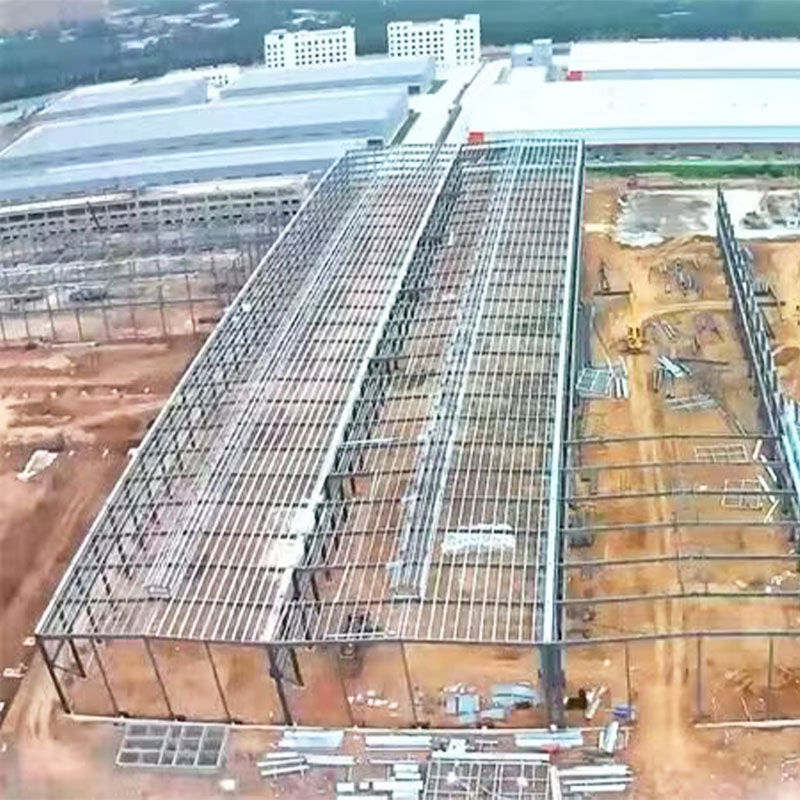

Installation and Construction

Installation is a key link in the process of steel structure engineering.Firstly, according to the requirements of the construction drawings, the embedded parts are installed on the foundation or columns to prepare for the subsequent lifting of steel columns.Then, the appropriate lifting machinery is selected to lift the steel column to the specified position, and the temporary fixation and correction are carried out. Next, steel beams, purlins, support systems and other components are installed to ensure the stability and safety of the structure.During the entire installation process, construction codes and standards should be strictly followed to ensure the quality and safety of construction.

Post maintenance

Steel structure engineering in the use of the process, the need for regular maintenance and maintenance.This includes the application of fire-retardant coatings, anti-corrosion coatings and other protective measures to extend the service life of the structure and maintain its aesthetics.

Custom

Communication needs: drawings, communication and customization; No drawings, communication needs

Confirm the plan: confirm the drawing and confirm the details

Issue a quotation: confirm the delivery date and determine the mode of delivery

Cash on order

Packaging and delivery: preferred shipping, real-time tracking of logistics information

After-sales service: installation guide